Corrugated Steel Structure (CSS), which was applied in North America in the early 1900s and has been installed in more than 1,000,000 places worldwide, has been in service since 1996, 100 years later, in Korea with POSCO, Korea Expressway Corporation, Seoul National University, Hanyang University, etc. It has been applied to the domestic market through commercialization research by specialized companies. Based on this, since the 2000s, it has been widely applied to road crossing passages, waterways and local small rivers, animal movement ecological passages, and Piam tunnels. Based on the advantages and economic feasibility of minimizing the existing vehicle traffic control during construction, it is a universal new construction method along with the existing reinforced concrete construction method. About 5000 corrugated steel plate structures have been installed and operated in Korea for 20 years.

However, regarding the various advantages of the construction method and the rapidly occurring demand, in the beginning, detailed explanations of the national design standards and specifications were insufficient. Problems such as deformation of the corrugated steel sheet occurred intermittently due to the lack of understanding of the backfill material and backfill compaction, which are the most important factors in

To improve this, ChungAmEnC has continuously improved and supplemented related standards through R&D with various related organizations, and based on domestic and foreign failure cases, provides optimized design solutions in advance for possible problems during actual construction. Optimized solutions include Virtual Construction: a three-dimensional system for step-by-step forecasting processes. (BIM LoD: 350 / Tekla, Trimble) and 3D Scanning (Leica P30 System, Cyclone ) Minimize errors that may occur at each construction stage I did. In addition, by providing 3D FEM, 3D printing and landscape design solutions, we will do our best to become a company that continuously develops and provides the world's best solutions that overcome the uncertainty of design and construction anxiety that customers have felt.

History of CSS

In 1896, an American civil engineer James. H. Watson and Starting with Stanley Simpson's patent, it was applied to small drainage channels in North America until the 1930s, and by the late 1900s, the maximum span was applied up to 11m and expanded to small bridges, passageways, and military facilities (ammunition depots). Since the 2000s, the span has been extended to 23m and applied to ecological tunnels, mine stockpiles, reclaim tunnels, and military facilities (hangars). 2014-2016 R&D and commercialization of extra-corrugated corrugated steel sheet (EXSCor) of Cheongam EnC With success, the maximum span was extended to 40m. It satisfies the maximum loads of CAT 797F (about 620 tons), EURO LM71, mine trucks, which could not be applied in the past with respect to live loading along with the expansion of span, so that it is economical, stable, and workable than concrete structures in multi-step processes. has enough competitiveness. In addition, extra corrugated steel sheet (EXSCor) is listed as a construction method and product according to design standards in Korea (KDS, KCS) as well as AASHTO LRFD and ASTM A796M in the United States.

Solution Rock & Soil Sliding Prevent Tunnel Solution

Rock & Soil Sliding Prevent Tunnel

On the road where 70% of the land was inevitably built for a long time in mountainous conditions, during the rainy season and thawing season, due to landslides or rock sliding due to the transition of the incision surface, a lot of property, casualties, and a lot of damage caused by road control every year. National and personal losses are occurring. Therefore, damage that occurs every year should be minimized by installing piam tunnels in steep slopes and areas where sliding may occur.

As a general method that can be applied, the rebar and concrete pouring method is applied at the site. However, there is the inconvenience of having to control traffic for a long time due to the long construction period, and sudden sudden surges that may occur due to natural disasters during the construction period are inconvenient. Special measures should be prepared for safety accidents due to sliding of rocks and soil. The construction cost does not secure competitiveness with pre-fabrication products pre-fabricated at the factory.

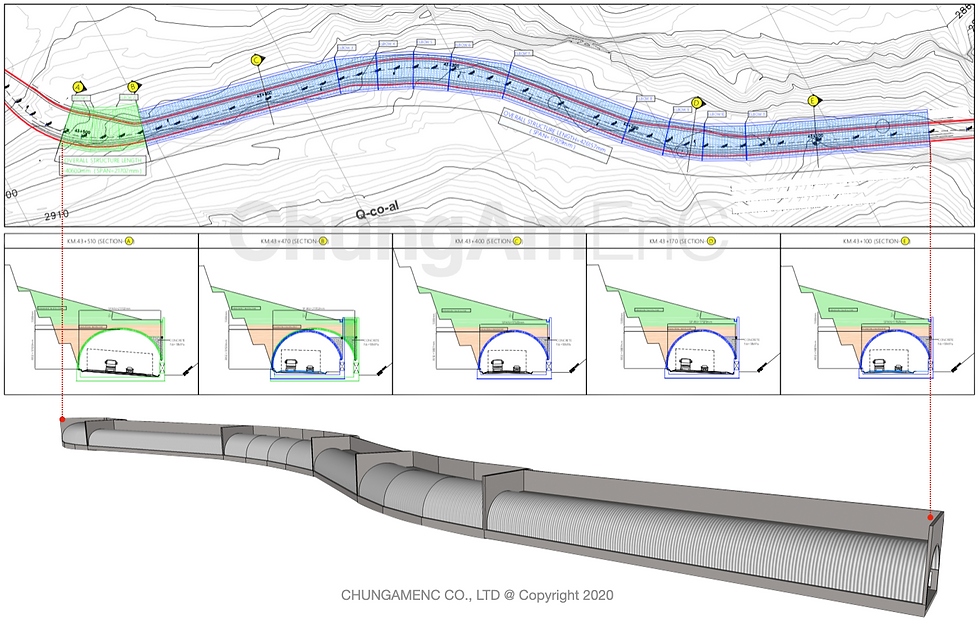

Solution Corrugated steel sheet is a construction method that is generally made with the balance of soil and soil on both sides, and when an eccentric action is applied from one side, many problems may occur in the stability of the structure of the corrugated steel sheet. Accordingly, when designing a corrugated steel sheet in a Piam tunnel, FEA analysis (MIdas GTS NX, Midas Civil) is performed based on the ground data that has been pre-examined for stress and response conditions on one side (soil and rock slide) to calculate member force. , selection of the corrugated section of corrugated steel sheet that can cope with it (from 2016, the application of the super-frame type, in which the secondary moment of section increased more than 3 times compared to the existing rib type, is advantageous for stability), steel type, thickness, presence or absence of reinforcement, and reinforced concrete retaining walls and sidewalls Design the foundation.

In addition, since the Piam Tunnel is mainly installed on the existing road on a steep slope, it has excellent field applicability by applying the 'Built-up Beam to the Elbow' manufactured in the factory in advance according to the road alignment.

For all safety factors (SF: Safety Factor) corresponding to design stability, design review is performed with SF: 150%~200% or more, which is higher than the safety factor of general corrugated steel sheets (SF: 120%, 100% or more is OK). (Considering the stress exceeding the design requirement in case of continuous increase in precipitation and fall due to climate change) In addition, FEA Simulation (retaining wall construction, backfill stage, Concrete pouring pressure, live load conditions for each compaction equipment, etc.), the structural safety factor (SF) of the corrugated steel sheet used in the past was sufficiently secured by applying the 'extra corrugated steel sheet (EXSCor)', and the economic feasibility In terms of constructability, it has sufficient competitiveness to satisfy customers.

1. Design Workflow

2. FEA Modeling

3. FEA Modeling based on Construction Procedure

4. FEA Result

*For detailed structural invoices and FEA reports, please request the structural analysis team of ChungAmE&C.

5. Construction Status_October 2018 ~ May 2019

6. Upper plan of corrugated steel plate Fiam tunnel

The plan is to horizontally flatten the upper part of the Fiam Tunnel with soil and to construct a slope in advance to move the soil and rocks coming down from the steep slope to the opposite side (cliffs and rivers) from the upper part of the Fiam Tunnel. Recently, in overseas sites, when the upper part of the Fiam Tunnel is leveled horizontally, it cannot withstand the stress of sliding down soil and collapse or repair and reinforcement is frequently required. As a solution, the 'upper inclination angle of up to 30 degrees' was requested. Accordingly, as shown in Figures 1 & 2, our company planned the condition to flow down to the opposite side even if the soil and rocks slide by configuring the inclination angle of the upper soil up to 30 degrees , and the corresponding structural design service was completed.

In Korea, a 20 degree slope was designed in the 'Piam Tunnel of Gangwon-do Yeonha-grade Slope' designed in 2016, and a supplementary plan for additional sliding was established and construction was completed.

7. Case Study