Corrugated Steel Structure (CSS), which was applied in North America in the early 1900s and has been installed in more than 1,000,000 places worldwide, has been in service since 1996, 100 years later, in Korea with POSCO, Korea Expressway Corporation, Seoul National University, Hanyang University, etc. It has been applied to the domestic market through commercialization research by specialized companies. Based on this, since the 2000s, it has been widely applied to road crossing passages, waterways and local small rivers, animal movement ecological passages, and Piam tunnels. Based on the advantages and economic feasibility of minimizing the existing vehicle traffic control during construction, it is a universal new construction method along with the existing reinforced concrete construction method. About 5000 corrugated steel plate structures have been installed and operated in Korea for 20 years.

However, regarding the various advantages of the construction method and the rapidly occurring demand, in the beginning, detailed explanations of the national design standards and specifications were insufficient. Problems such as deformation of the corrugated steel sheet occurred intermittently due to the lack of understanding of the backfill material and backfill compaction, which are the most important factors in

To improve this, ChungAmEnC has continuously improved and supplemented related standards through R&D with various related organizations, and based on domestic and foreign failure cases, provides optimized design solutions in advance for possible problems during actual construction. Optimized solutions include Virtual Construction: a three-dimensional system for step-by-step forecasting processes. (BIM LoD: 350 / Tekla, Trimble) and 3D Scanning (Leica P30 System, Cyclone ) Minimize errors that may occur at each construction stage I did. In addition, by providing 3D FEM, 3D printing and landscape design solutions, we will do our best to become a company that continuously develops and provides the world's best solutions that overcome the uncertainty of design and construction anxiety that customers have felt.

History of CSS

In 1896, an American civil engineer James. H. Watson and Starting with Stanley Simpson's patent, it was applied to small drainage channels in North America until the 1930s, and by the late 1900s, the maximum span was applied up to 11m and expanded to small bridges, passageways, and military facilities (ammunition depots). Since the 2000s, the span has been extended to 23m and applied to ecological tunnels, mine stockpiles, reclaim tunnels, and military facilities (hangars). 2014-2016 R&D and commercialization of extra-corrugated corrugated steel sheet (EXSCor) of Cheongam EnC With success, the maximum span was extended to 40m. It satisfies the maximum loads of CAT 797F (about 620 tons), EURO LM71, mine trucks, which could not be applied in the past with respect to live loading along with the expansion of span, so that it is economical, stable, and workable than concrete structures in multi-step processes. has enough competitiveness. In addition, extra corrugated steel sheet (EXSCor) is listed as a construction method and product according to design standards in Korea (KDS, KCS) as well as AASHTO LRFD and ASTM A796M in the United States.

We're Different

History of CSS

In 1896, the American civil engineer James. Starting with the patents of H. Watson and Stanley Simpson, in North America, it was applied to small drainage channels until the 1930s, and by the late 1900s, the maximum span was applied up to 11m and expanded to small bridges, passageways, and military facilities (ammunition storage). Since the 2000s, the span has been extended to 23m and applied to ecological tunnels, mine stockpiles, reclaim tunnels, and military facilities (hangars). 2014-2016 Through the successful R&D and commercialization of extra corrugated steel sheet (EXSCor) by Cheongam EnC, the maximum span has been expanded to 40m. It satisfies the maximum loads of CAT 797F (about 620 tons), EURO LM71, mine trucks, which could not be applied in the past with respect to live loading along with the expansion of span, so that it is economical, stable, and workable than concrete structures in multi-step processes. has enough competitiveness. In addition, extra corrugated steel sheet (EXSCor) is listed as a construction method and product according to design standards in Korea (KDS, KCS) as well as AASHTO LRFD and ASTM A796M in the United States.

General Information

Corrugated steel sheet is 92 times stronger than standard steel (Pitch: 150mm, Depth 50mm), 842 times stronger than steel before processing, and 842 times higher for corrugated steel (Pitch: 381mm, Depth 140mm). ) silver (Pitch: 500mm, Depth 237mm) is 2,466 times ① corrugated steel sheet with increased rigidity ➞ ② machining the curvature as requested in the drawing ➞ ③ creating bolt holes that can be assembled ➞ ④ molten zinc for durability It is plated and brought to the site. ➞ ⑤ At the site, the assembly is completed by connecting with high-tensile bolts. ➞ ⑥After waterproofing around the bolts and the overlapping parts of the corrugated steel sheet and the corrugated steel sheet (tiling tile assembly) ➞ ⑦ This is a structure that is completed by applying the backfilling materials and compaction required in the structural invoice and specification.

Solution Improvement

In the design of corrugated steel sheet, the most important factors for securing stability, such as joint test, bending test, and box-type haunchi part test, were performed. Various materials (KS D 3503 fy:275MPa, fy:315MPa, fy:450MPa) and thickness Steel structure design standards (KDS 14 31 10: 2017: Ministry of Land, Infrastructure and Transport), Standard Specification for Road Construction (KCS 11 40 10: 2016: Ministry of Land, Infrastructure and Transport), defense, military It satisfies the facility standards (DMFC 4-10-70: 2009: Ministry of National Defense), and in the case of overseas exports, it meets ASTM A796M, AASHTO M167, and AS/NZS 2041.1:2011.

Bolt Connection Strength experiment

Bending test

haunch experiment

In addition, by producing and commercializing the super-bone type (EXSCor: Pitch: 500mm, Depth 237mm), which is the only one in Korea and produced by only 3 companies worldwide, it has a better quality than the existing large-bone type (Pitch: 381mm, Depth 140mm). By increasing the required amount by only 8~9%, it has about 3 times the stiffness of the secondary moment of section, which is economical and has the production capacity and engineering capability of corrugated steel sheet with more stability.

Experimental video_Land Transport Infrastructure Research Institute

Typical Section Library Service

We have optimized the Rise Ratio to Span along with the increase in the rigidity of the EXSCor. Due to the nature of the civil engineering site, the customer's desired cross section actively provided. From span 2m up to 40m, based on each span, 8~9 optimal section ratios (30%~85% / Box shape: 20%~65%) are configured, and approximately 440 cross-section standard drawings (Typical Section Library) By having a CAD file, we can provide it to our customers in a timely manner. Of course, by providing the quantity of corrugated steel sheet for each section and the optimal cover height, it is provided along with the OCT results at the time of initial planning and design. *Please consult ChungAmEnC's engineer for request for Typical Section Library when establishing a section plan.

Solution Engineering Service

We provide One-Stop service through OCT Program (Optimization Comparison Table). The OCT Program is a smartphone (Android Version) and web-based program, and all our engineers use ①395,872 library databases to ➞ ②select the optimal section in real time ➞ ③ the optimal section for the site requirements. When selecting the steel type, backfill material and backfill compaction degree (sub-base material, subgrade soil, compaction ratio 95%, 90%, 85%), site conditions should be sufficiently reflected, ➞ ④ Thickness of corrugated steel sheet (weight per m) It is possible to compare prices through calculation), and the stability of the structure (marking the safety factor according to the standards of each country) can be provided immediately. ➞ ⑤ In addition, by providing the stress value for the concrete foundation, it provides optimized engineering that secures the stability of the corrugated steel sheet for the overall construction cost, not just the comparison of the corrugated steel sheet construction cost when establishing a structure plan. After planning the optimal structure through the use of OCT Program, we provide all engineering services related to corrugated steel sheet through an internal program that automatically calculates structural invoices, design drawings, and quantity calculations.

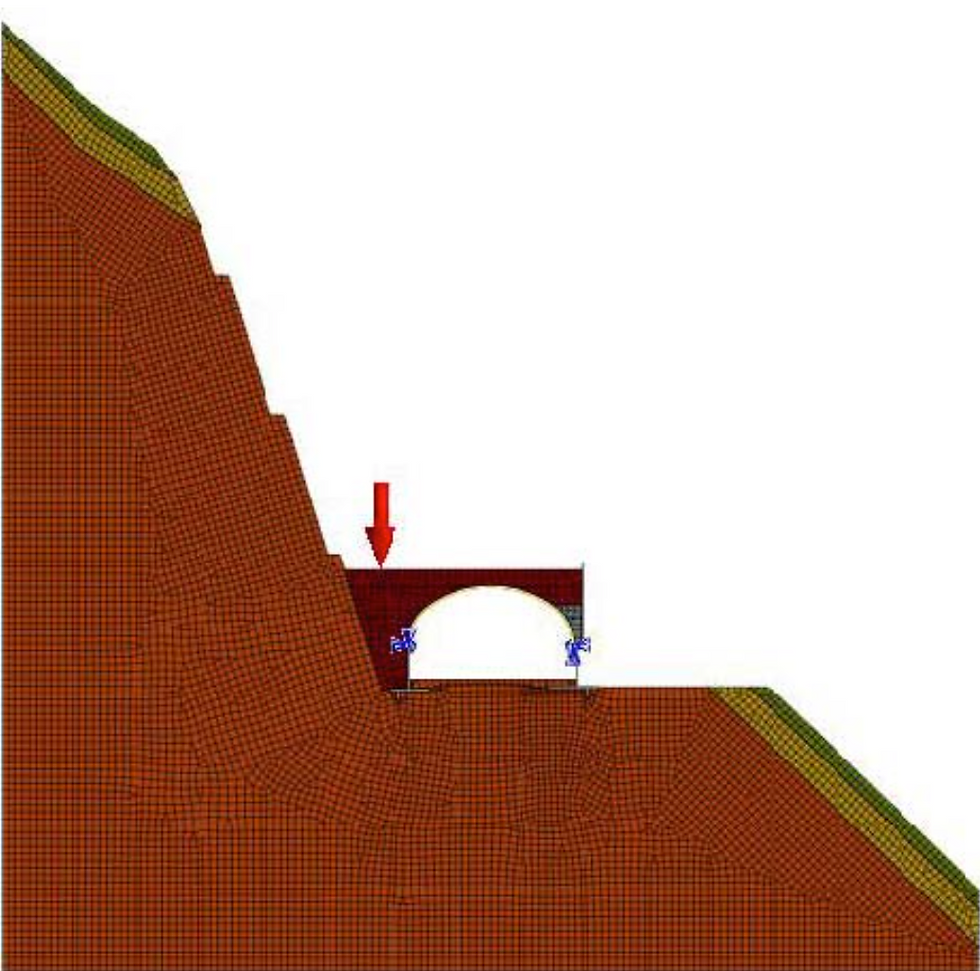

FEA: ① In the case of structures under flat earth pressure conditions, when the cover height is excessively high, and when there are special characteristics of the site conditions ➞ ② Through 3D, 2D modeling computational analysis (FEA: Midas GTX, ABAQUS, Midas Civil, CANDE), We provide engineering services that predict generated moment, axial force, and displacement and reflect it in structural calculations.

3D Scan Monitoring: By introducing the latest technology 3D Scanning system (Lieca® 3P, Cyclone®, TrueView®) technology for the first time in the industry, our company performs a monitoring service of the structure, and through this, the three-dimensional backfill stage, displacement after completion, and final cover height Investigation work within ±3mm provide.

Building Information Method (BIM): By applying BIM from the corrugated steel sheet planning stage for the first time in the world, we tried to help customers fully understand the site planning and details in three dimensions. As the BIM detailed design stage is designed at LoD350*Level of Development or higher, the object properties of all applied materials are provided. This is a design method that also considers future maintenance. In addition, detailed data for each construction stage is provided so that there are no errors in the field, and the on-line viewer is used to share with customers on smartphones and PCs .